Packaging and eco-design

We’ve set our target: a 46% reduction in CO2 emissions by 2030*! How are we going to reach it?

FPM and the DIAM Group have committed to implementing sustainable packaging.

This decarbonation trajectory has been scientifically validated as aligned with a 1.5°C trajectory and the Paris Agreement on Climate Change by the Science-Based Target initiative (SBTi), the reference independent organization on this matter.

Our cases, boxes, kits, displays, and more – at the crossroads of excellence and sustainability.

Our environmental approach can be summarized in one word: eco-design!

Let us tell you all about it.

*A common classification for all companies allows measuring carbon emissions in 3 scopes.

We plan to reduce our CO2 emissions by 46% by 2030 vs 2019 for scopes 1 & 2, which concern energy consumption of production sites. Additionally, we aim to reduce our environmental impact by two-thirds for scope 3, which includes all other emissions generated across the entire value chain.

What does eco-design mean?

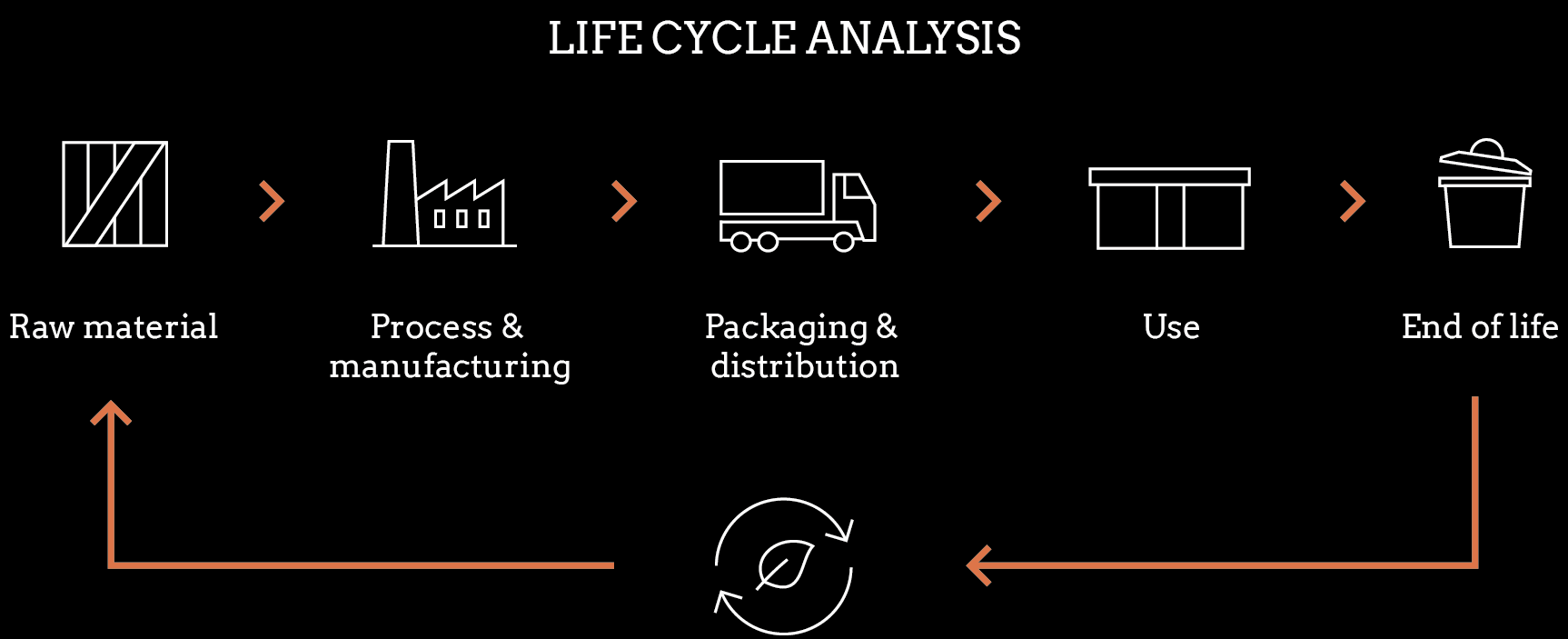

Eco-design is an approach that aims to reduce a product’s environmental impact from the design phase all the way to the end of its lifespan.

Here at FPM, our eco-design policy builds on product Life Cycle Analysis (LCA), as set out in ISO standards 14040 and 14044. Whether it’s raw material, production, or transport, and so on, we study every stage in the lifespan of packaging to identify the areas with the heaviest environmental impact.

How do we measure a product’s environmental impact?

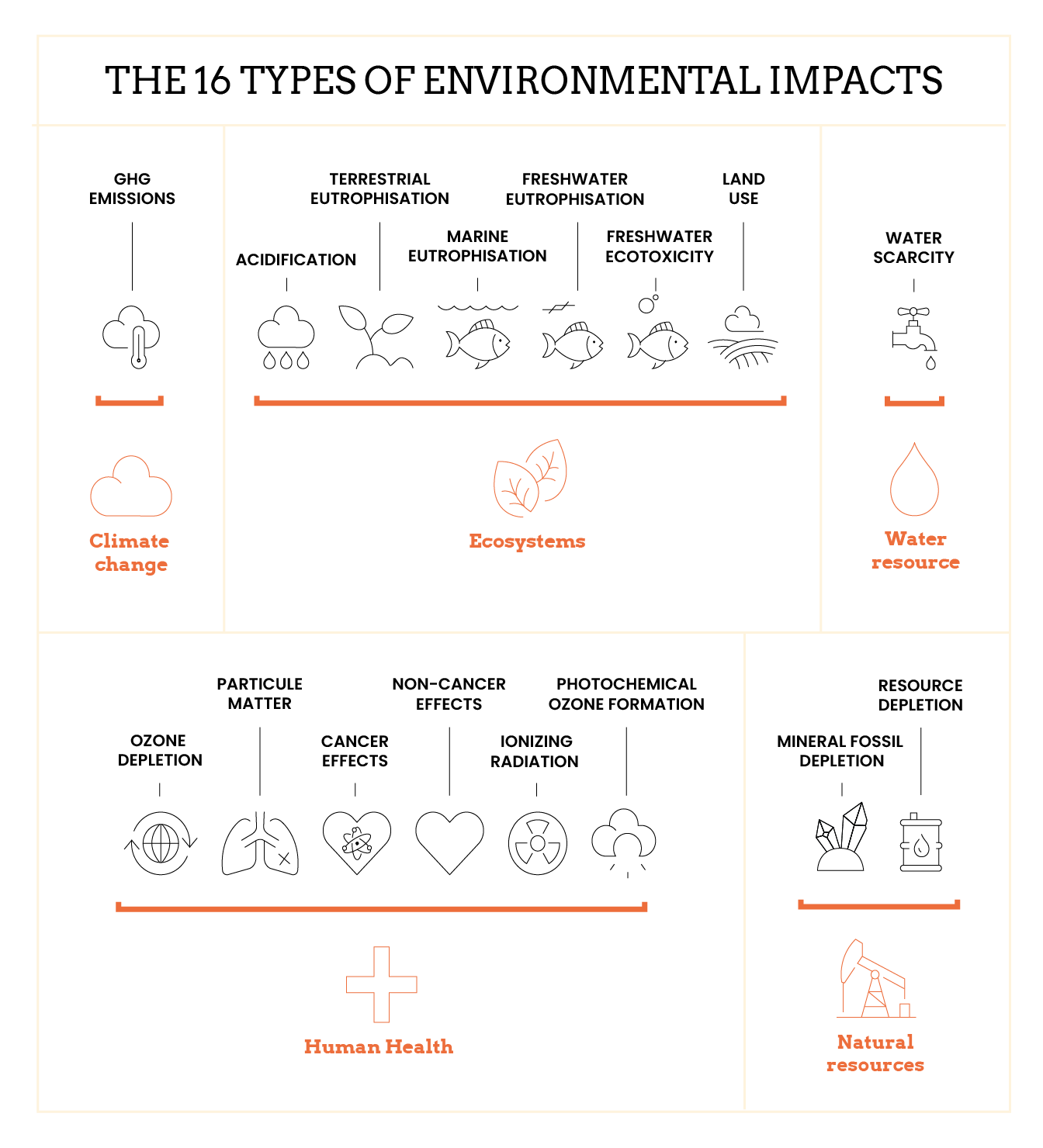

Environmental impact is more than just CO2 emissions. To measure it, we consider 16 criteria encompassing the entire environment, and interpret them in relation to a World resident’s average yearly environmental impact (according to the Product Environmental Footprint initiative recommendations) to facilitate decision making.

For example, producing a raw material might release low CO2 emissions and have a relatively minor impact on climate change, yet trigger much more significant consequences on the ecosystem and biodiversity through water pollution.

The ecological rating on FPM’s packaging is therefore based on all 16 of these criteria.

Eco-design: a methodology that offers concrete solutions

Eco-design allows us to consider a product’s environmental impact from the very beginning. The design phase defines 80% of the packaging’s final impact. The last 20% can then be adjusted according to secondary criteria during supply or production.

The eco-design checklist:

- Proposing different aesthetics to allow for alternative materials

- Prioritizing lightweight materials

- Using recycled or certified materials, sourcing “clean” materials

- Modifying sizes to reduce weight

- Reinventing closures / openings (reducing glue and metal accessories as much as possible, rethinking cushioning, etc.)

- Avoiding or minimizing excess and shipping packaging

- Optimizing a product’s end-of-life by, for example, creating structures that can be broken down and recycled more easily, encouraging product reuse.

With the DIAM Group’s support, our teams at FPM have been trained in every step of eco-design while maintaining our packaging’s high quality and aesthetic requirements. Beyond eco-design, we have optimized our factories to limit our environmental footprint on scopes 1 & 2 (building insulation, electricity consumption – over 95% of our electricity comes from renewables, etc.). Our sourcing is constantly improving, and we’re very careful in our choice of transportation (avoiding plane journeys).

Can’t wait to eco-design together!

FPM teams